Overview of Arc Welding Machine

Welding is a process by which one can join two similar metals and alloys by melting the metal itself or by depositing filler material via a consumable electrode/stick or wire. The process realized its true potential back in the late 19th century when it was commercially used for fabrication jobs in shipbuilding, vehicle manufacturing, and steel industry.

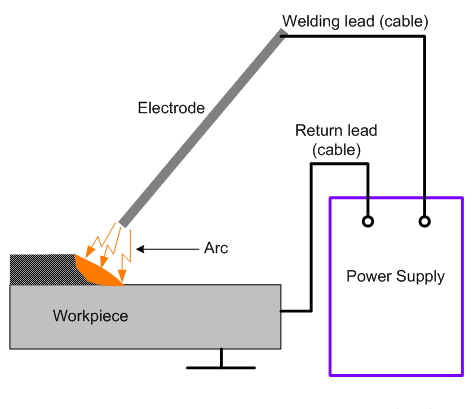

Welding is usually done by creating an arc between the base metals and electrode, which in turn creates heat and aids in deposition of material either from filler materials (Welding electrodes, Welding wires) or from the base metal, creating a pool of weld between the jobs that need joining; explaining why it’s commonly known as Arc Welding.

To make sure a precise, high- tech, cost-effective and reliable weld; welding operation has become the most critical among other processes in industry and in order to ensure high-quality final products there is a continuous endeavor to improve the quality of welds. All this makes matching the best welding machines for the right job all the more valuable and can be the difference between an opportunity for profit or a loss on the job.

List of Free Tips to Buy an Arc Welding Machine

Fortunately or unfortunately there is no “one fits all” welding process and the factors which need to be considered while boiling down on a specific process and a corresponding welding machine are:-

- Type of base metal

- Thickness of job

- Welding position

- Duty Cycle/Time requirement

- Power Source type and technology

- Type of current

Now I know, it is quite easy to be overwhelmed but if you continue reading, it will definitely get easier.

#1)Welding Process

With the advancement of technology, welding processes have become more specific and technologically advanced than ever and here is the chart below to list down the process suitable for joining different base metals and alloys.

#2)Stick Welding

Shielded Metal Arc Welding (SMAW) or Stick Welding, commonly also referred to as simply Arc Welding is the most conventional process used to weld. It uses arc formed between the base metal and a consumable electrode (stick-shaped) to deposit filler material at the job. This process is also popular as its economical and its ability to effectively join on rusty & dirty jobs, indoors and outdoors.

Stick Welding is however difficult to learn, use and the process is also limited by the thickness of the job and it usually ranges between 1mm to 25mm. At Industrybuying, we have a wide range of Stick Welding machines that come in either AC or DC or AC-DC and their selection depends upon the penetration required. Electrodes are usually kept positively charged to ensure greater heat concentration and thus higher weld penetration and speed, alternatively thinner workpieces need lesser penetration and have negatively charged electrodes.

So, the AC welding machine is the preferred choice among arc welding machines as it keeps alternating the polarity and helps produce medium-penetration while the electrodes help in both creating the arc as well in depositing filler material.

Selecting the right power source with the right amperage is the next important thing to be taken care of. Here is a list of our premium Arc welders curated just for you. With the advent of cutting edge technology power sources nowadays have a lot to offer.

The intended use also factors in deciding whether the power source should be of Single phase or Two-Phase or Three-phase according to their use for individual or industrial applications. Selecting the technology of power sources is a little difficult as both transformer-based source and an inverter-based source has its own pros and cons.

#3)Arc Quality

When discussing welding machines, we can’t ignore arc performance and the welds produced. If you are one of those who regularly welds on the mild steel, you won’t have to look past the transformer machine.

#4)Versatility

You now can buy inverter welding machines on which you can adjust just about any electrical variable imaginable with software to create unmatched versatility. Unlike transformer machines, the Inverter machines are lighter and more portable.

#5)Reliability

This is most debated aspect when comparing the two power sources and frankly, transformers have a slight edge, given the time the transformer technology had for innovation and improvement to create a rugged and reliable machine. However, inverters are the way to go as the gap between the two has narrowed considerably in recent years. Industrybuying offers an exclusive range of waterproof inverter-based welding machines with replacement warranties, now we don’t think it can get better than this.

Whether you are a hobbyist, a seasoned welder or an inquisitive customer, we have the right product for you with us from brands like Esab, Miller, Lincon, Ador, Panasonic, Great, EWM, Ralliwolf, budget machines, and many others. Industrybuying brings to you Arc Welding Machine which use various techniques for quality weld such as Inverter Based, Diode Based, IGBT Based, Transformer Based (Aluminium Winding), IGBT Rectifier, IGBT (M) Technology, IGBT Based Inverter, MOSFET and Thyristor Based Welding machine.

So go ahead and check out the wide range of Arc welding machines online at Industrybuying.com and we would love to assist you in making that decision and all you have to do is get in touch.

Why to buy Arc Welding Machine online at Industrybuying.com?

Industrybuying.com is your one-stop destination for any requirement of the Welding machine or any other Welding tools or equipment. The company assorts a wide range of Top welding tools manufacturers online. Be it exclusive discounts on 100% original products or a seamless online shopping experience Industrybuying makes sure that the customers experience the best online shopping experience.

You can find all the welding tools such as Flame Arrestors, Gas Adapters, Gas Cutting Accessories, Gas Filter, Gas Pressure, Regulator, Gas Valve, Non-Return Valve, TIG Rod, Welding Accessories, Welding Electrodes, Welding Machine or Welding Wire at affordable prices online at Industrybuying.com. For any professional assistance, you can reach out to us at our toll-free number 1800-300-09551.

Average Rating